Your Complete Guide to PVC Pipe in Compressed Air Systems

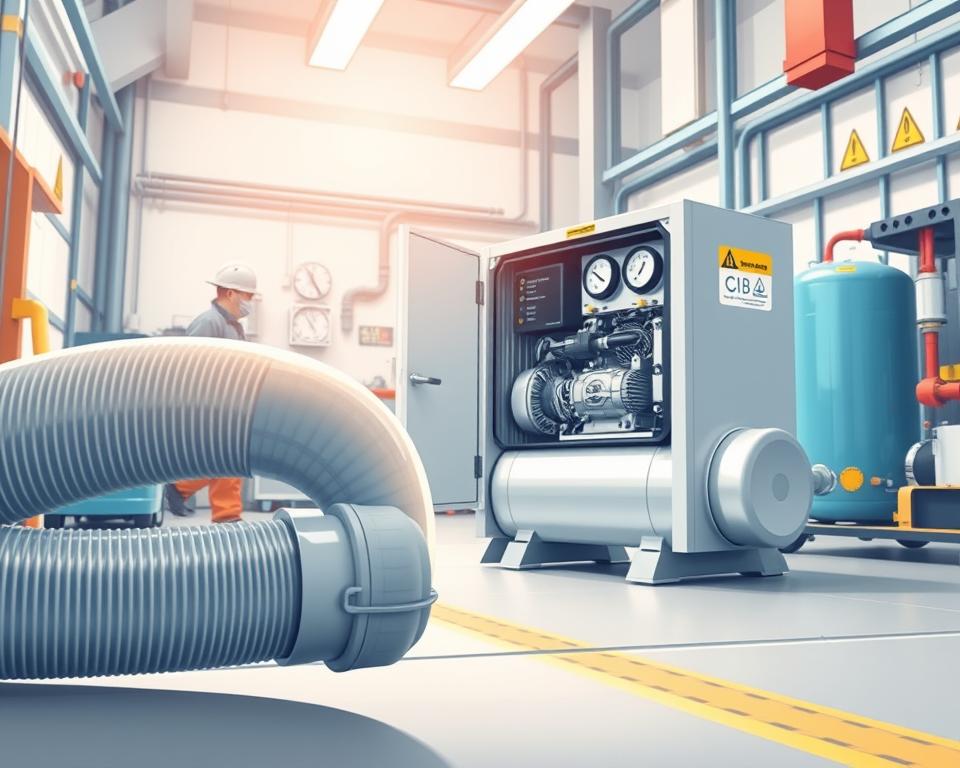

A burst compressed air line can discharge energy comparable to a stick of dynamite—did you know? Despite the hazards, numerous workshops continue installing piping systems from unsafe materials. Here’s why you must prioritize safety over cost when selecting PVC for air lines.

Even as interest rises, OSHA bans these materials for above-ground compressed air. Over time, exposure to oils and temperature changes weakens them, leading to catastrophic failures. Safe-rated pressures can still result in deadly bursts.

For reliable alternatives, Installation Parts Supply offers durable solutions like aluminum. Using approved materials saves you from fines and enhances safety. Let’s explore how to build a safer system.

Main Takeaways

- OSHA prohibits specific piping for air lines because of blast hazards.

- Pressure ratings drop as temperatures fluctuate.

- Material becomes brittle with age, upping rupture chances.

- Switching to aluminum vastly improves safety.

- Proper investment prevents costly fines and accidents.

Why You Shouldn’t Use PVC for Compressed Air

PVC makers caution never to employ it in high-pressure air setups. Compressed air carries destructive energy; a burst is like a dynamite blast. This makes material choice critical for safety.

- Brittleness: Sub-freezing temperatures turn materials brittle, increasing fracture risks.

- Adhesive failures: Joints weaken when exposed to compressor oils or temperature swings.

- Misleading ratings: Ratings halve by 110°F, a common shop temperature.

OSHA cites a $110,000 fine after a facility’s piping shattered, injuring workers. Compression heating lowers allowable pressure even more—often ignored.

“Above-ground use of certain plastics for compressed air violates OSHA standards due to explosion risks.”

Metal alternatives fail more predictably, bending rather than fragmenting. Fragments from PVC blasts can hurl past 50 feet, embedding dangerously.

Workshops face daily temperature fluctuations that accelerate material degradation. A decade’s UV and chemical attack weakens plastic, so small leaks too often balloon into disasters.

Recommended Piping Materials for Compressed Air

Modern aluminum systems beat old-school piping on both safety and performance. With 90% fewer leaks than black pipe, they’re a top choice for modern facilities. Lightweight, rust-proof aluminum stands up to years of service.

Snap-together modular aluminum cuts installation hours. Installation Parts Supply stocks ready-to-snap aluminum modules. One auto factory trimmed labor hours by 40% via aluminum retrofits.

- Copper: Ideal in sterile environments for its germ-killing copper surface. Requires soldering expertise.

- Stainless Steel: Stainless steel stands up to salty, moist conditions.

- ABS/HDPE: Chemical-resistant for labs and factories handling solvents.

“Our aluminum retrofit reduced energy waste by 15%—paying for itself in 18 months.”

Don’t ignore torque specs. Cracks from overtightening and leaks from under-tightening are common. Stick to recommended 25–30 ft-lb torque for aluminum.

Use NSF-certified materials when air quality is critical. Choose pipe rated for your specific operating environment.

Selecting the Best Air Compressor Piping

Consider cost, compliance, and efficiency in your pipe decision. A Midwest factory saved $12,000 annually by switching to leak-resistant aluminum. Follow these tips to pick wisely.

| Material | Cost (per ft) | Maintenance | ROI Time |

|---|---|---|---|

| Aluminum | $8.50 | Low | 18 months |

| Black Pipe | $5.00 | High | N/A |

| Copper | $10.20 | Medium | 24 months |

Don’t ignore thermal limits. Plastics fail under 32°F; aluminum works from -40°F to 200°F. For chemical-heavy environments, stainless steel resists solvents.

Pro Tip: Use leak-loss math to estimate ROI. A 10% leak in a 50 HP system wastes $3,500 yearly.

- Ensure your pipe PSI rating exceeds system pressure.

- Keep records of inspections and tests to satisfy OSHA.

- Contact Installation Parts Supply for a no-cost audit.

“Our aluminum retrofit cut energy waste by 15%—paying for itself in 18 months.”

Small shops can DIY, but experts deliver guaranteed seals. Check warranties—some pipes include decade-long coverage.

The Bottom Line

Choosing the right materials for your compressed air setup isn’t just about cost—it’s about safety. Older systems account for 92% of accidents due to degraded piping. With 99.8% uptime, aluminum is the clear long-term choice.

Key takeaways:

- Never use pipes that can fragment violently.

- Choose rust-proof metals over plastics.

- Ignoring standards invites fines and insurance headaches.

Upgrade now and secure your workplace. Installation Parts Supply provides same-day quotes and limited-time discounts on starter kits. Request your free template or emergency service today.

Make safety your piping priority—act today.